| Availability: | |

|---|---|

| Quantity: | |

| Model | BBA-5441LS with Blowing type feeder |

| Moving Range | X/Y1/Y2/Z 500*400*400*100MM |

| Max Jig Size | 200*280*70(MM) |

| Power Supply | AC110V/220V, 50HZ/60HZ |

| Air Pressure | 0.4 to 0.8 Mpa |

| Moving Speed | X, Y 600-800 MM/S, Z 400MM/S |

| Control System | Module driver+Teach Pendant |

| Feeder Mode | Blowing type |

| Applicable screw | M1-M8 |

| Working efficiency | 1.0s/screw |

| Driving Mode | Closed-loop precison Motor |

| Alarm System | Screw Stripped and Loose Alarm |

| Screwdriver type | Brushless screwdriver |

| Torque Range | Depends on Products |

| Repeated Accuracy | +/-0.02MM |

| Weight | 98(KG) |

| Dimension of the machine | 850*750*500(MM) |

| Working Environment | Temp 0-40℃, Humidity 20%-95% |

| Model | BBA-5441LS with Blowing type feeder |

| Moving Range | X/Y1/Y2/Z 500*400*400*100MM |

| Max Jig Size | 200*280*70(MM) |

| Power Supply | AC110V/220V, 50HZ/60HZ |

| Air Pressure | 0.4 to 0.8 Mpa |

| Moving Speed | X, Y 600-800 MM/S, Z 400MM/S |

| Control System | Module driver+Teach Pendant |

| Feeder Mode | Blowing type |

| Applicable screw | M1-M8 |

| Working efficiency | 1.0s/screw |

| Driving Mode | Closed-loop precison Motor |

| Alarm System | Screw Stripped and Loose Alarm |

| Screwdriver type | Brushless screwdriver |

| Torque Range | Depends on Products |

| Repeated Accuracy | +/-0.02MM |

| Weight | 98(KG) |

| Dimension of the machine | 850*750*500(MM) |

| Working Environment | Temp 0-40℃, Humidity 20%-95% |

1.Blow type feeding mode comparing to pick-up feeding mode, saving time of pick the screws back and forth.

2.Available for M1-M8 screw.

3.Deep-hole screw fastening is available.

4.High reliability, automatic alarm system, working >20 hours.

5.It has the detection functions of leak lock,sliding teeth,floating lock and so on,which can effectively reduce QC work.

6.Only adjusting the fixture can realize screw locking of different products, and the utilization rate of equipment is high.

7.Can be customized according to the special requirements.

1.Blow type feeding mode comparing to pick-up feeding mode, saving time of pick the screws back and forth.

2.Available for M1-M8 screw.

3.Deep-hole screw fastening is available.

4.High reliability, automatic alarm system, working >20 hours.

5.It has the detection functions of leak lock,sliding teeth,floating lock and so on,which can effectively reduce QC work.

6.Only adjusting the fixture can realize screw locking of different products, and the utilization rate of equipment is high.

7.Can be customized according to the special requirements.

- Double Y-axis platform, left and right locking screws are alternated.

- Air type screw conveying, automatic screw tightening.

- Continuous feeding, providing the screw count function and anti-missing function.

- Constant torque, screw loose thread and float lock, alarm function.

- Three-axis linkage, high lock efficiency.

- It is independent mold. It is an aluminum profile casting structure with clean look.

- It has a teaching pendant which is fast and easy to program.

- It is controlled by a high precision stepping motor to ensure the accuracy.

- Double Y-axis platform, left and right locking screws are alternated.

- Air type screw conveying, automatic screw tightening.

- Continuous feeding, providing the screw count function and anti-missing function.

- Constant torque, screw loose thread and float lock, alarm function.

- Three-axis linkage, high lock efficiency.

- It is independent mold. It is an aluminum profile casting structure with clean look.

- It has a teaching pendant which is fast and easy to program.

- It is controlled by a high precision stepping motor to ensure the accuracy.

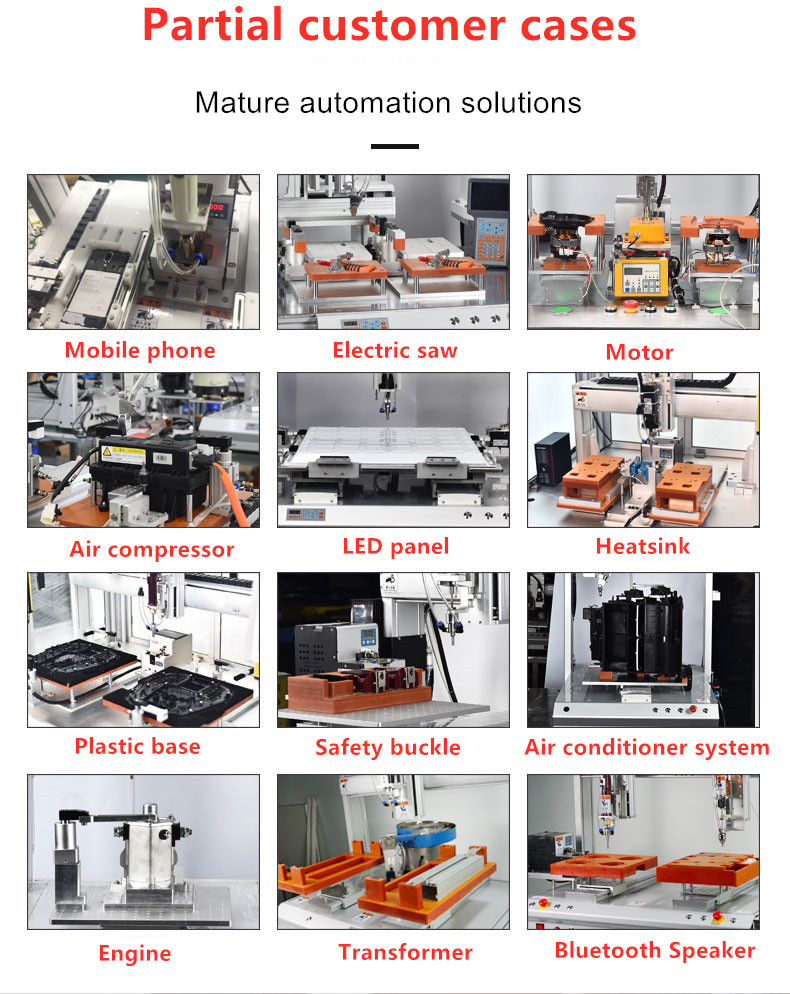

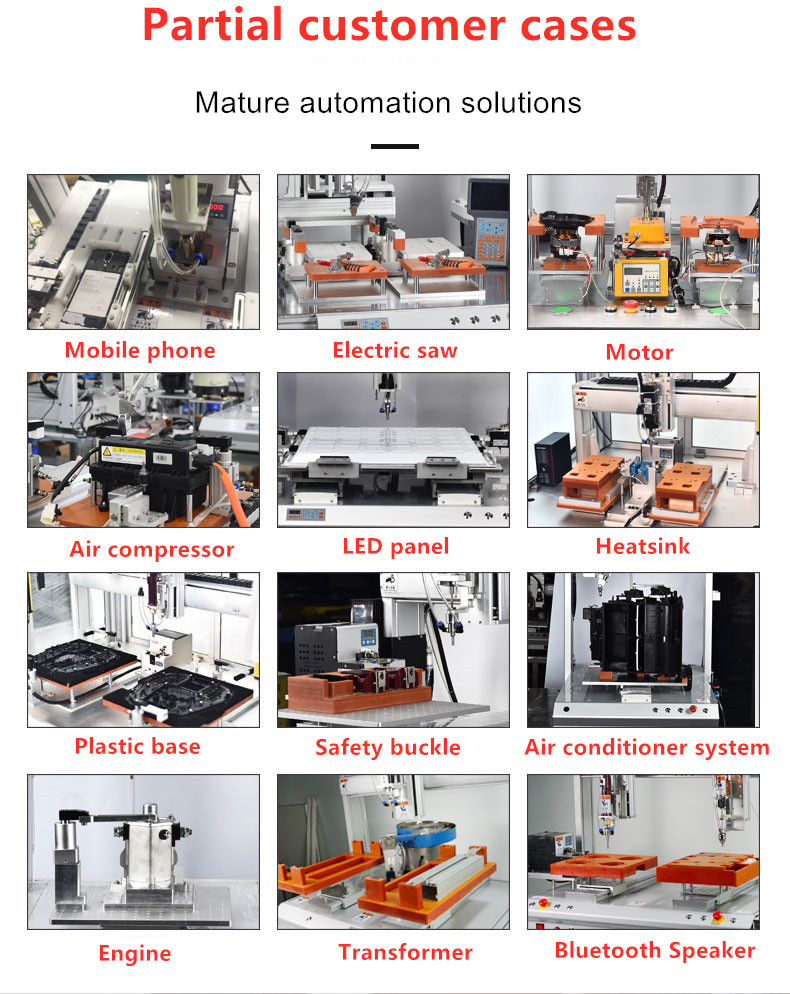

- Communication industry: such as mobile phone, camera, hard disk, keyboard, printer, computer, DVD, home appliance, plastic, toy etc.

- Audio industry: In many processes, parts have many screw processes.

- The toy assemble: Due to the continuous innovation and variety of products, the use of automatic locking screw machine is undoubtedly a good choice. It plays an important role in improving efficiency or saving cost. The automatic screw locking machine has strong adjustability and can meet the diversified needs of toy industry.

- Hardware assembly industry: such as motor, motor parts assembly and other fields. The use of automatic screw locking machine instead of manual operation not only reduces the labor cost, but also improves the production efficiency.

- Communication industry: such as mobile phone, camera, hard disk, keyboard, printer, computer, DVD, home appliance, plastic, toy etc.

- Audio industry: In many processes, parts have many screw processes.

- The toy assemble: Due to the continuous innovation and variety of products, the use of automatic locking screw machine is undoubtedly a good choice. It plays an important role in improving efficiency or saving cost. The automatic screw locking machine has strong adjustability and can meet the diversified needs of toy industry.

- Hardware assembly industry: such as motor, motor parts assembly and other fields. The use of automatic screw locking machine instead of manual operation not only reduces the labor cost, but also improves the production efficiency.

- 7*24 online service.

- Provide operation instructions and videos to teach step by step.

- One-year warranty except for consumables, the other parts can be replaced free of charge within one year.

- Provide free training at our factory.

- Provide standard export wooden package.

- Lead time: standard:5-10 days. Customized: 15-20days.

- CE certificates are available.

- 7*24 online service.

- Provide operation instructions and videos to teach step by step.

- One-year warranty except for consumables, the other parts can be replaced free of charge within one year.

- Provide free training at our factory.

- Provide standard export wooden package.

- Lead time: standard:5-10 days. Customized: 15-20days.

- CE certificates are available.